You can also choose to add the eC Reflow Mate PCB-holder that provides absolute flexibility in terms of adjustments, and is ideal for small boards. Stress-free soldering with Reflow Solder ovens.

#Pcb reflow oven install#

All you need is a fumeĮxtraction device and the space to install it on premises.

#Pcb reflow oven manual#

The oven also has a large window on theįront-panel that makes manual process evaluation easy. The Reflow Oven comes with a 3.5-inch LCD touch-screen installed in the machine for selecting, starting, and stopping a profile’s process. With comprehensive graphics, information processing and analysing for virtually unlimited profiles becomes Safely and accessibly store your time and temperature profiles on your systems.

#Pcb reflow oven software#

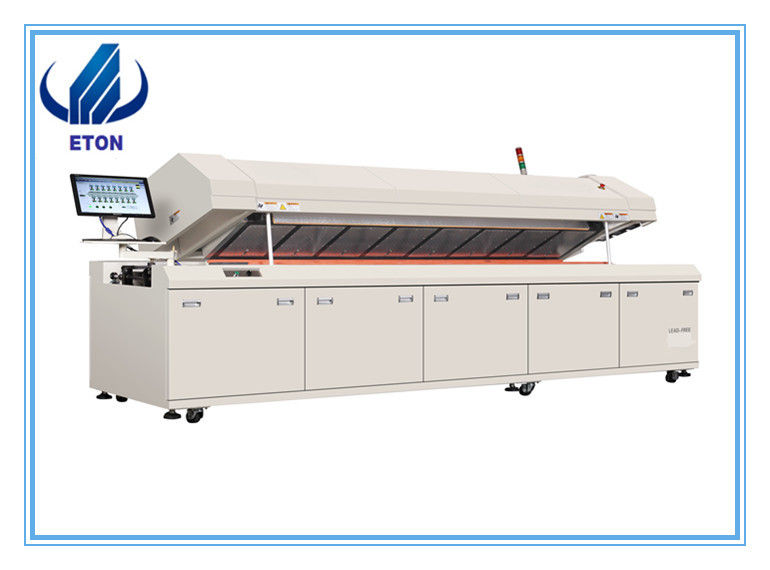

Custom-Engineered Interface and Software for Ease of Use: The eC Reflow mate comes with the eC Reflow Pilot software that allows you to.From benchtop batch solder reflow ovens to automatic floor. The 2000HT hot-air reflow system utilizes our patented Horizontal Convection Heating technology with digital temperature controls for extremely uniform air circulation and temperature. PCB Unlimited offers various solder reflow ovens with options to accommodate low to high volumes. Designed for Safety: The oven comes in an insulated casing that helps in ensuring the energy loss is controlled to the lowest-possibleĭenominator and the air circulation within the oven is safe. Higher throughput SMT reflow oven with 20' (508mm) wide conveyor for production runs.The 32-bit arm processor lendsĪdditional control by storing 5 profiles that can expedite the individual process. The oven comes with a drying function that carries pre-set profiles helping in quick deployment and reconfiguration of temperature & time profiles. Automatic drawer opening post reflows have been designed to minimise the risk of board stress by enabling faster The oven providesĭrawer-access, resulting in an increased ease of loading & unloading. PCB reflow oven with Conveyor in a 41 (1042mm) long heating tunnel for low volume lead and lead-free reflow soldering. Optimized Soldering Cycle: Achieved with the help of IR lamps for pre-heating and fast subsequent heat-up.Units available with a maximum temperature of 400C (752F) and can be used for lead or lead-free solder applications. You can also choose to add the eC Reflow Mate PCB-holder that provides absolute flexibility in terms of adjustments, and is ideal for small boards. The 1800HT solder reflow oven utilizes our patented Horizontal Convection heating technology for extremely uniform temperature profiling across the board for enhanced reflow surface-mount process control. The Reflow Oven comes with a 3.5-inch LCD touch-screen installed in the machine for selecting, starting, and stopping a profile’s process. Xinzhou offers industrial ovens such as reflow ovens for drying printed circuit boards, such as infrared oven, conveyor oven and walk-in oven for customers. Designed for Safety: The oven comes in an insulated casing that helps in ensuring the energy loss is controlled to the lowest-possibleĭenominator and the air circulation within the oven is safe. 10 Years+ Turnkey PCB Assembly Manufacturer, Provides SMD Reflow Soldering &DIP Assembly Services.The 32-bit arm processor lendsĪdditional control by storing 5 profiles that can expedite the individual process. What Is Smt Reflow Oven A reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards (PCBs). The oven providesĭrawer-access, resulting in an increased ease of loading & unloading. Description SMTmax reflow oven family of high-throughput thermal processing system is widely recognized as.

0 kommentar(er)

0 kommentar(er)